|

As for the domestic seamless aluminum veneer processing technology, the veneer processing technology here mainly includes fluorocarbon spraying, polyester spraying and powder spraying.

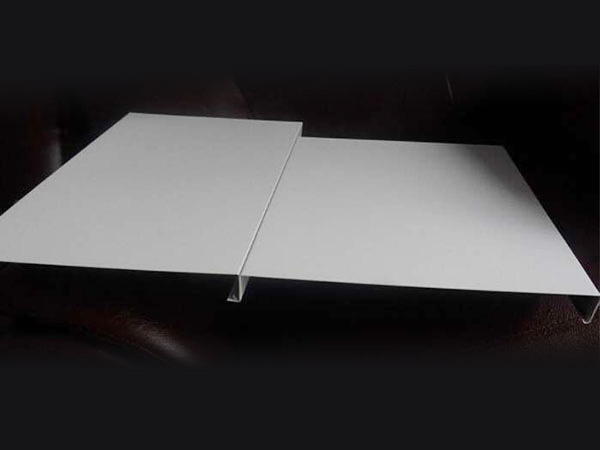

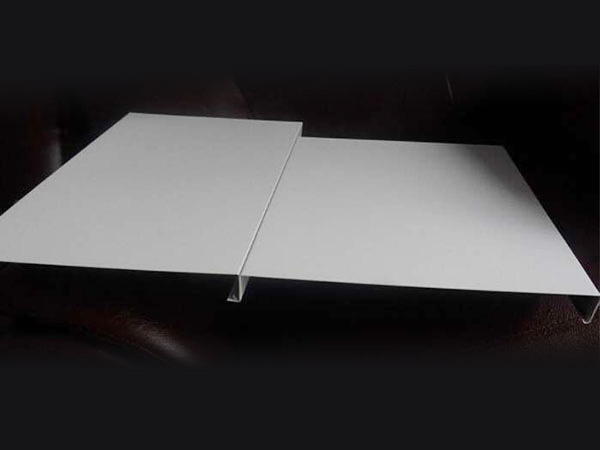

The spraying production of seamless aluminum veneer is divided into two main steps: the first step is sheet metal processing. This process is mainly used to process the aluminum plate into the shape and size required for construction through such processes as cutting, folding, electric bending, welding and grinding of the plate. The second step is spraying. Spraying is to spray paint or powder on the processed metal plate.

As for the domestic seamless aluminum veneer processing technology, the veneer processing technology here mainly includes fluorocarbon spraying, polyester spraying and powder spraying.

The spraying production of seamless aluminum veneer is divided into two main steps: the first step is sheet metal processing. This process is mainly used to process the aluminum plate into the shape and size required for construction through such processes as cutting, folding, electric bending, welding and grinding of the plate. The second step is spraying. Spraying is to spray paint or powder on the processed metal plate.

There are two types of seamless aluminum veneer spraying, one is manual spraying and the other is mechanical spraying.

Mechanical spraying is generally only applicable to ordinary flat plates, but this kind of aluminum veneer is rarely used in practice. Most domestic manufacturers use manual spraying. Manual painting is a dangerous work, because volatile and toxic paint or powder is relatively strong, it is easy to cause chronic benzene series poisoning and seriously affect people's health.

One advantage of manual spraying is that the size and color can be selected, and the roll coating of aluminum-plastic plate must reach a certain amount before processing. The processing process of aluminum-plastic plate is more complicated than that of aluminum veneer, mainly including forming, coating, compounding, trimming and other processes. Except trimming, all are automatic production. From its processing technology, it can be seen that aluminum-plastic plate has certain advantages in environmental protection and safety. In addition, the metal sheet processing technology of aluminum veneer is simple, and some private workshops have also started to get involved, which has seriously affected the stability of the market quality of seamless aluminum veneer.

86-755-23499577

86-755-23499577